Wastewater treatment plants play a vital role in maintaining public health and protecting the environment, but they also face one of the most common challenges—odor control. The unpleasant smells from sewage and industrial effluents can cause discomfort to workers and nearby communities, often leading to complaints and regulatory concerns.

In this blog, we’ll explore the causes of odors in wastewater treatment facilities, the technologies used to manage them, and best practices for long-term odor control.

Why Do Wastewater Treatment Plants Smell?

Odors in wastewater treatment plants are primarily the result of anaerobic decomposition—the breakdown of organic matter in the absence of oxygen. This process releases various gases, the most notorious being:

-

Hydrogen Sulfide (H₂S): Rotten egg smell

-

Ammonia (NH₃): Pungent, irritating odor

-

Volatile Organic Compounds (VOCs): Organic chemicals that contribute to foul smells

These gases are typically released during processes such as sludge digestion, primary sedimentation, aeration, and sludge dewatering.

Common Sources of Odor in Treatment Plants

-

Influent channels and headworks

-

Primary clarifiers

-

Sludge thickening and dewatering areas

-

Anaerobic digesters

-

Equalization tanks and pumping stations

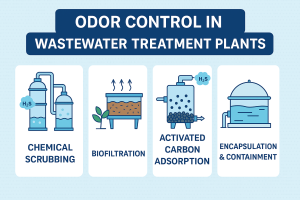

Odor Control in Wastewater Treatment Plants Method

1. Chemical Scrubbing

Chemical scrubbers use reagents (like sodium hydroxide, bleach, or sulfuric acid) to neutralize odorous gases. These are widely used for hydrogen sulfide removal.

Pros:

-

High removal efficiency

-

Suitable for high odor concentrations

Cons:

-

Requires chemical handling and disposal

-

Can be expensive over time

2. Biofiltration

Biofilters use a natural process in which microorganisms break down odorous compounds. Air is passed through a bed of organic media (like compost or wood chips), where bacteria degrade the odors.

Pros:

-

Environmentally friendly

-

Low operating cost

Cons:

-

Requires regular maintenance of media

-

Sensitive to environmental changes

3. Activated Carbon Adsorption

Activated carbon filters trap and adsorb odor molecules on their surface.

Pros:

-

Simple to install and operate

-

Effective for low flow and low concentration odors

Cons:

-

Media replacement needed

-

Less effective for very strong odors

4. Oxidation and Ozonation

Oxidizing agents like ozone or hydrogen peroxide chemically react with odor compounds, neutralizing them.

Pros:

-

Fast and effective

-

Can treat a wide range of compounds

Cons:

-

High capital and operating costs

-

Safety concerns with ozone generation

5. Encapsulation & Containment

Physically enclosing odor-generating sources (like tanks or sludge presses) and treating the captured air using filtration systems.

Pros:

-

Prevents odor from escaping

-

Works well with secondary treatment technologies

Cons:

-

High installation costs

-

Requires good design and airflow control

Best Practices for Odor Management

-

Regular Maintenance: Clean and inspect tanks, pipes, and pumps to prevent buildup.

-

Monitoring Systems: Install sensors to detect H₂S and other odor-causing gases.

-

Preventive Measures: Add chemicals like ferric chloride or nitrate salts in sewers to reduce sulfide formation.

-

Community Communication: Keep residents informed and involved to manage expectations and reduce complaints.

-

Employee Training: Ensure staff are trained to respond quickly to odor-related issues.

Odor control in wastewater treatment plants is more than just about comfort—it’s about community trust, environmental compliance, and operational efficiency. With the right combination of technology, design, and preventive practices, plants can manage odors effectively and sustainably. Investing in odor control not only enhances the plant’s image but also contributes to a healthier environment for everyone.